Oil Analyzers Fluid Analysis

The Oil Analyzers Fluid Analysis Program protects valuable equipment by providing solutions for lubrication concerns through accurate and easy-to-understand fluid analysis, timely reporting and an unparalleled commitment to personal, friendly customer service. Oil Analyzers works with fully equipped laboratories staffed by highly trained analysts and offers a complete line of oil analysis services to help you get the most from your lubricants and extend the life of your equipment.

- Personalized Service. Oil Analyzers provides personalized customer service. Reports are easy to understand and recommendations are included so you know exactly what you should do to provide the best care for your equipment. In addition, Oil Analyzers customer service representatives are available by phone and email to answer questions.

- High-Quality Testing. Oil Analyzers Fluid Analysis is performed at independent ISO 17025 A2LA accredited testing laboratories. This is the highest level of quality attainable by a testing laboratory backed by the most stringent accrediting body in the industry. You can be confident that the results you receive are accurate, repeatable and traceable to a standard.

- Innovative Information Technology Solutions. Oil Analyzers online reporting software, HORIZON®, delivers your results almost immediately after sample processing is complete. The software’s management reports take your fluid-analysis program to the next level by helping you manage your data and your program efficiently and effectively.

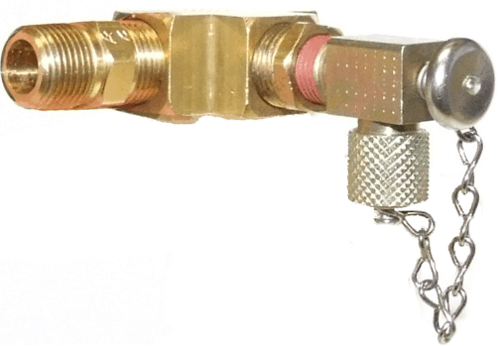

Oil Sample Valve for BMK 30 Bypass System

Fluid Analysis Helps You Save Money

Because fluid analysis provides a comprehensive look at the condition of lubricants and internal component wear, tracking sample results over a period of time can help save money.

- Maximize oil drain intervals. Monitoring the condition of the oil allows you to optimize drain intervals so that you capitalize on the fluid’s full service life. Performing fewer oil changes minimizes maintenance costs and maximizes uptime.

- Extend equipment life. Monitoring system cleanliness and filtration efficiency can help you keep your equipment longer and significantly reduce replacement costs.

- Prevent major problems. State-of-the-art fluid analysis identifies dirt, wear particles, fuel dilution, coolant and other contaminants that can cause catastrophic failure or significantly shorten equipment life.

- Maximize asset reliability. Testing and analysis ensure that equipment is up, running and making money.

- Increase resale value. Analysis results provide valuable sampling history documentation that justifies higher equipment resale values.

Whatever your comments, suggestions or questions,

we welcome you to Contact Us!

The best ways to reach us are via our Contact Us page, or by calling us toll free at

1-800-581-5823 between 8 am and 9 pm CST Monday through Saturday.

You are welcome to 'Like" us on Facebook where we share news about our AMSOIL products and customers.

Please follow us on our LinkedIn Company Page for news as well.

If you're on Twitter, you'll find us at @vaughn_inc

You're welcome to follow our AMSOIL product news bites there as well.

Remember, the best way for you to reach us is via the contact us page on this website or by calling toll free 1-800-581-5823 between 8 am and 9 pm CST Monday through Saturday.

Whatever your interest we welcome your inquiry!